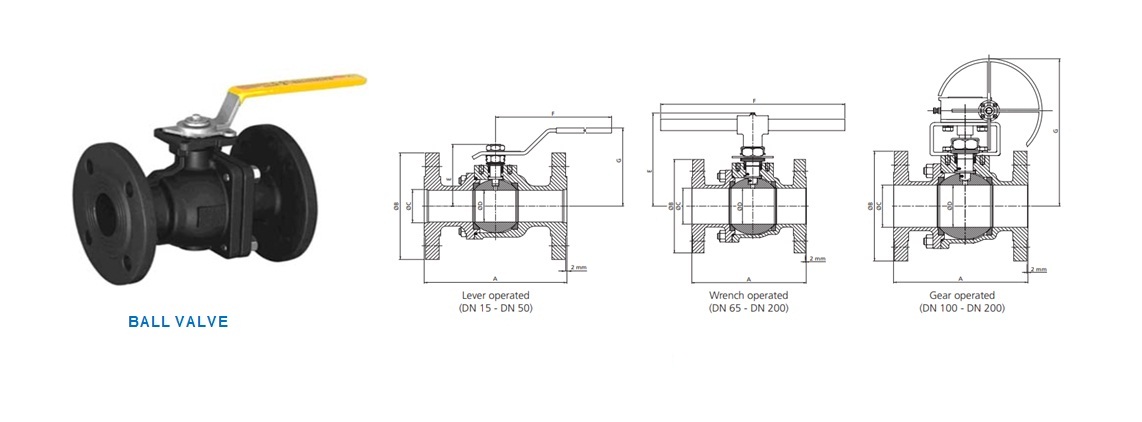

TWO PIECE FLOATING BALL VALVE

Gusto’s Two Piece Floating Ball Valve is a high-quality valve that is designed to provide reliable and durable performance in a variety of applications. This valve is made from high-quality materials and is designed to meet the highest standards of quality and performance.

PURPOSE

The purpose of Gusto’s Two Piece Floating Ball Valve is to provide reliable and efficient control of fluids in a variety of industries, including oil and gas, chemical processing, and power generation. This valve is specifically designed to provide accurate and precise control of fluid flow, ensuring that fluids are transported efficiently and safely.

BENEFITS

The Two Piece Floating Ball Valve offers a number of benefits, including its high-quality construction, durability, and reliability. This valve is made from the highest quality materials, ensuring that it is able to withstand even the most demanding conditions. It is also designed to be easy to install and maintain, making it a cost-effective solution for fluid control needs.

APPLICATIONS

The Two Piece Floating Ball Valve is used in a variety of applications, including oil and gas pipelines, chemical processing plants, power generation facilities, and more. This valve is specifically designed to provide accurate and precise control of fluid flow, making it an ideal choice for applications where fluid flow control is critical.

The different parameters, as well as the size and material of the valve as per the tables, illustrations and details given in this page, to ensure that our valves match the requirements of your specific application.

If you’re looking for a reliable and high-quality valve solution, look no further than Gusto’s Two Piece Floating Ball Valve. With its durable construction, precise control, and cost-effective design, this valve is the perfect choice for a wide range of fluid control applications.

CONTACT GUSTO’S EXPERTS TODAY TO HELP YOU CHOOSE THE RIGHT VALVE !

| Valve Size inch (mm) | A | B | C | D | E | F | G | WEIGHT (Kgs) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CL 150 | CL 300 | CL 150 | CL 300 | CL 150 | CL 300 | CL 150 | CL 300 | |||||

| ½” (15) | 108 | 140 | 90 | 95 | 13 | 11 | 38 | 38 | 120 | 90 | 1 | 2 |

| ¾” (20) | 117 | 152 | 100 | 115 | 19 | 17 | 45 | 45 | 120 | 90 | 2 | 3 |

| 1” (25) | 127 | 165 | 110 | 125 | 25 | 24 | 55 | 55 | 158 | 97 | 3 | 4 |

| 1.1/2” (40) | 165 | 190 | 125 | 155 | 38 | 37 | 75 | 75 | 212 | 122 | 5 | 6 |

| 2” (50) | 178 | 216 | 150 | 165 | 51 | 49 | 103 | 103 | 212 | 142 | 9 | 12 |

| 3” (80) | 203 | 282 | 190 | 210 | 76 | 74 | 185 | 195 | 390 | – | 19 | 28 |

| 4” (100) | 229 | 305 | 230 | 255 | 102 | 98 | 235 | 247 | 600/890 | – | 31 | 45 |

| 6” (150) | 394 | 403 | 280 | 320 | 152 | 148 | 285 | 315 | 890/980 | – | 78 | 105 |

| 8” (200) | 457 | 502 | 345 | 380 | 203 | 198 | 345 | 371 | 980 | – | 142 | 169 |

TECHNICAL DATA

Design & Mfg Std : ISO 17292/API 6D

Insp & test Std : ISO 5208/API 598

Range : 15mm to 150mm

Pressure Rating : 150/300

End Connection : Flange End as per B16.5

Type : Flange Type

Moc : C.I/WCB/CF8/CF8M/CF3/CF3M

Trims : S.S 410/CF8/CF8M

Seat : DEVLON/RPTFE/PTFE

Operation : Lever/Gear/Actuator