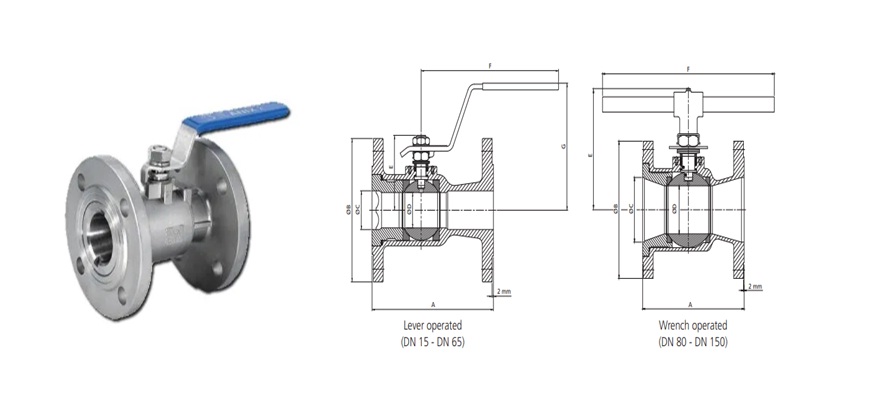

SINGLE PIECE FLOATING BALL VALVE

Gusto’s single-piece floating ball valve is a reliable and efficient valve designed for various industrial applications. It is a high-performance valve made from quality materials, ensuring its durability and longevity.

PURPOSE

The purpose of Gusto’s single-piece floating ball valve is to provide an effective solution for controlling the flow of fluids and gases in different industrial processes. It is designed to provide a tight seal, preventing any leakage or flow interruption, making it ideal for critical applications.

BENEFITS

Gusto’s single-piece floating ball valve offers several benefits to its users. Its compact design ensures easy installation and maintenance, while its high-quality materials provide excellent resistance to corrosion and wear, extending its lifespan. Its efficient sealing system ensures minimal leakage, which helps in reducing operational costs. Moreover, its low-torque operation results in energy savings, making it a cost-effective option for various industrial applications.

APPLICATIONS

Gusto’s single-piece floating ball valve is widely used in various industrial sectors, including chemical, petrochemical, oil and gas, pharmaceutical, food and beverage, and water treatment industries. It is ideal for controlling the flow of fluids and gases in pipelines, tanks, reactors, and other applications.

The different parameters, as well as the size and material of the valve as per the tables, illustrations and details given in this page, to ensure that our valves match the requirements of your specific application.

Investing in Gusto’s single-piece floating ball valve means investing in a reliable and durable solution for your fluid control needs. With its high-quality materials, advanced engineering, and superior performance, this valve can ensure long-lasting, leak-free operation in a variety of industrial applications. Trust in Gusto’s expertise and experience to provide you with the best solution for your fluid control needs.

CONTACT GUSTO’S EXPERTS TODAY TO HELP YOU CHOOSE THE RIGHT VALVE !

| Valve Size inch (mm) | A | B | C | D | E | F | G | WEIGHT (Kgs) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CL 150 | CL 300 | CL 150 | CL 300 | CL 150 | CL 300 | ||||||

| ½” (15) | 108 | 140 | 90 | 95 | 13 | 11 | 38 | 120 | 90 | 1 | 2 |

| ¾” (20) | 117 | 152 | 100 | 115 | 19 | 11 | 38 | 120 | 90 | 1 | 2.5 |

| 1” (25) | 127 | 165 | 110 | 125 | 25 | 17 | 46 | 140 | 100 | 2 | 4 |

| 1.1/2” (40) | 165 | 190 | 125 | 155 | 38 | 27 | 56 | 180 | 115 | 4 | 4.5 |

| 2” (50) | 178 | 216 | 150 | 165 | 51 | 37 | 75 | 210 | 122 | 6.5 | 9 |

| 3” (80) | 203 | 282 | 190 | 210 | 76 | 62 | 175 | 390 | – | 15.5 | 22 |

| 4” (100) | 229 | 305 | 230 | 255 | 102 | 74 | 195 | 390 | – | 25 | 35 |

| 6” (150) | 267 | 403 | 280 | 320 | 152 | 98 | 245 | 600/890 | – | 40 | 65 |

TECHNICAL DATA

Design & Mfg Std : ISO 17292/API 6D

Insp & test Std : ISO 5208/API 598

Range : 15mm to 150mm

Pressure Rating : 150/300

End Connection : Flange End as per B16.5

Type : Flange Type

Moc : C.I/WCB/CF8/CF8M/CF3/CF3M

Trims : S.S 410/CF8/CF8M

Seat : DEVLON/RPTFE/PTFE

Operation : Lever/Gear/Actuator