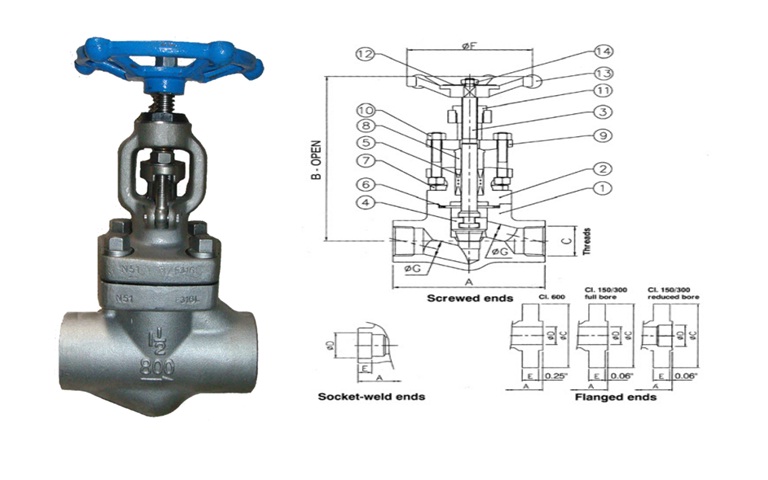

FORGED GLOBE VALVE 150, 300, 600 & 800

Gusto’s Forged Globe Valve is a type of industrial valve that controls the flow of fluid in pipelines by partially or completely blocking the flow. The valve consists of a body, a bonnet, a stem, and a disc. The body and bonnet are usually made of forged steel, which provides durability and resistance to corrosion and high pressure.

PURPOSE

The purpose of Gusto’s Forged Globe Valve is to regulate the flow of fluid, whether it is gases, liquids, or steam, and control the pressure in pipelines. It is used in various applications such as water treatment, power generation, chemical processing, and oil and gas production.

BENEFITS

The benefits of using a Forged Globe Valve include:

Durability : The valve body and bonnet are made of forged steel, making it suitable for high pressure applications and providing resistance to corrosion.

Precision Control : The disc of a globe valve can be precisely positioned to control the flow of fluid, making it ideal for applications that require fine flow regulation.

Easy Maintenance : The design of the valve makes it easy to maintain, as the internal parts can be accessed by removing the bonnet.

Versatility : Globe valves can be used for a wide range of fluid types and pressures, making it suitable for a variety of applications.

APPLICATIONS

- Process Industries: For controlling the flow of liquids and gases in chemical, petrochemical, and oil and gas industries.

- Generating Power: For governing the flow of steam in power plants.

- HVAC Systems: For controlling the flow of water in heating, ventilation, and air conditioning systems.

- Water Treatment: For controlling the flow of water in water treatment plants.

The different parameters, as well as the size and material of the valve as per the tables, illustrations and details given in this page, to ensure that our valves match the requirements of your specific application.

Invest in Gusto’s Forged Globe Valve and experience unparalleled performance, reliability, and durability. Trust us to provide you with high-quality valves that meet your specific needs and exceed your expectations.

So, why wait? Contact us today to learn more about our FORGED GLOBE VALVE and how it can benefit your operations.

CONTACT GUSTO’S EXPERTS TODAY TO HELP YOU CHOOSE THE RIGHT VALVE !

| Sl. No. | Description | Material |

|---|---|---|

| 1 | Body | ASTM A105, stellited seat |

| 2 | Bonnet | ASTM A105 |

| 3 | Stem | ASTM A479 Type 410 |

| 4 | Plug Disc | ASTM A217 Gr CA15 |

| 5 | Stem Packing | Graphite moulded rings with Braided top/bottom rings |

| 6 | Gasket | Spiral wound SS type 304 with graphite filler |

| 7 | Cap Screws | ASTM A193 Gr B7 |

| 8 | Gland Bush | ASTM A276 Type 410 |

| 9 | Gland Flange | ASTM A105 |

| 10 | Gland Stud / Nut | ASTM A276 Type 410 / ASTM A194 Gr 2H |

| 11 | Yoke Bush | ASTM A582 Type 416 |

| 12 | Identification Plate | SS |

| 13 | Hand wheel | SG Iron / Steel |

| 14 | Hand wheel Nut | Steel |

CLASS 150 / 300

Flanged ends (in inches, unless specified)

| Valve Size Inch (mm) | CLASS 150 / 300 GLOBE VALVES | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | øD | E | øF | |||||

| RB | FB | RB | FB | Class 150 | Class 300 | RB | FB | |||

| ½ (15) | 6.0 | 6.0 | 5.80 | 6.35 | 3.50 | 3.75 | 0.62 | 0.56 | 3.25 | 4.00 |

| ¾ (20) | 7.0 | 7.0 | 6.35 | 7.70 | 3.88 | 4.62 | 0.82 | 0.62 | 4.00 | 4.00 |

| 1 (25) | 8.0 | 8.0 | 7.70 | 9.55 | 4.25 | 4.88 | 1.05 | 0.69 | 4.00 | 5.50 |

| 1.1/4 (32) | 8.5 | 8.5 | 9.55 | 9.55 | 4.62 | 5.25 | 1.38 | 0.75 | 5.50 | 5.50 |

| 1.1/2 (40) | 9.0 | 11.5 | 9.55 | 11.60 | 5.00 | 6.12 | 1.61 | 0.81 | 5.50 | 7.25 |

| 2 (50) | 10.5 | – | 11.60 | – | 6.00 | 6.50 | 2.07 | 0.88 | 7.25 | – |

CLASS 600

Flanged ends (in inches, unless specified)

| Valve Size inch (mm) | CLASS 600 GLOBE VALVES | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | øD | E | øF | App Wt. (Kg) | ||||||

| RB | FB | RB | FB | RB | FB | RB | FB | RB | FB | |||

| ½ (15) | 6.5 | 6.5 | 5.8 | 6.4 | 3.75 | 0.50 | 0.62 | 0.56 | 3.25 | 4.00 | 3.6 | 5.4 |

| ¾ (20) | 7.5 | 7.5 | 6.4 | 7.7 | 4.62 | 0.75 | 0.82 | 0.62 | 4.00 | 4.00 | 5.4 | 7.4 |

| 1 (25) | 8.5 | 8.5 | 7.7 | 9.6 | 4.88 | 1.00 | 1.05 | 0.69 | 4.00 | 5.50 | 7.4 | 11.4 |

| 1.1/4 (32) | 9.0 | 9.0 | 9.6 | 9.6 | 5.25 | 1.25 | 1.38 | 0.81 | 5.50 | 5.50 | 11.4 | 13.5 |

| 1.1/2 (40) | 9.5 | 11.5 | 9.6 | 11.6 | 6.12 | 1.50 | 1.61 | 0.88 | 5.50 | 7.25 | 13.5 | 19.1 |

| 2 (50) | 11.5 | – | 11.6 | – | 6.50 | 2.00 | – | 1.00 | 7.25 | – | 19.1 | – |

CLASS 800

Screwed/socket-weld ends (in inches, unless specified)

| Valve Size inch (mm) | CLASS 800 GLOBE VALVES | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D (min) | E | F | G | App Wt. (kg) | |||||||

| RB | FB | RB | FB | RB | FB | RB | FB | RB | FB | |||||

| ¼ (8) | 3.20 | 5.8 | – | ¼ | – | 0.555 | 0.38 | 3.25 | – | 0.25 | – | 1.7 | – | |

| 3/8 (10) | 3.20 | 5.8 | 5.8 | 3/8 | 0.690 | 0.38 | 3.25 | 3.25 | 0.25 | 0.38 | 1.7 | 1.7 | ||

| ½ (15) | 3.20 | 5.8 | 6.4 | ½ | 0.855 | 0.38 | 3.25 | 4.00 | 0.38 | 0.50 | 1.7 | 2.4 | ||

| ¾ (20) | 4.00 | 6.4 | 7.7 | ¾ | 1.065 | 0.50 | 4.00 | 4.00 | 0.50 | 0.69 | 2.4 | 3.6 | ||

| 1 (25) | 4.85 | 7.7 | 9.6 | 1 | 1.330 | 0.50 | 4.00 | 5.50 | 0.69 | 0.94 | 3.6 | 6.8 | ||

| 1.1/4 (32) | 6.40 | 9.6 | 9.6 | 1.1/4 | 1.675 | 0.50 | 5.50 | 5.50 | 0.94 | 1.17 | 6.8 | 6.7 | ||

| 1.1/2 (40) | 6.40 | 9.6 | 11.6 | 1.1/2 | 1.915 | 0.50 | 5.50 | 7.25 | 1.17 | 1.44 | 6.7 | 10.8 | ||

| 2 (50) | 8.80 | 11.6 | – | 2 | – | 2.406 | 0.62 | 7.25 | – | 1.44 | – | 10.8 | – | |

TECHNICAL DATA

Construction : Out Side Screw & Yoke Type, bolted Bonnet

Design & Mfg Std : As Per Api602/Iso 15761

Insp & Test Std : As Per Api 598

End Connection : Socket Weld As Per Asme B16.11

Screwed End As Per Asme B1.20.1

Mac : Astm A 105, F304, F304I, F316, F316I, F5, F9 F11, F22, Lf2

Operation : Handwheel/Actuator