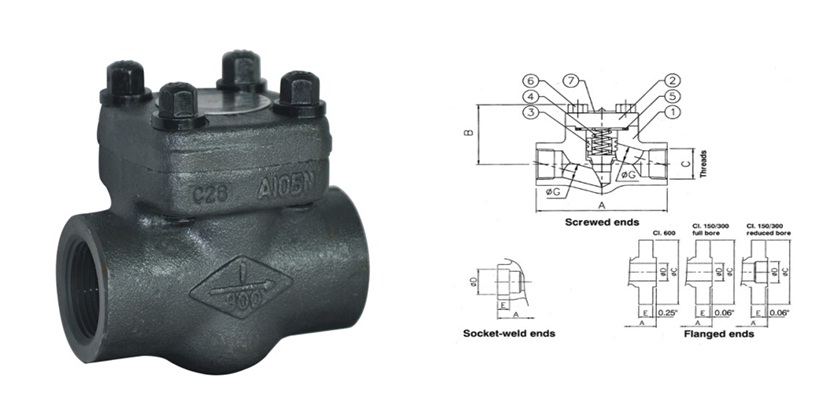

FORGED CHECK VALVE 150, 300, 600 & 800

Gusto’s Forged Check Valve is a type of check valve that is designed for high-pressure applications. It is made of high-quality forged steel, which makes it durable and long-lasting. This type of valve is commonly used in oil and gas, power generation, and chemical processing industries.

PURPOSE

The main purpose of Gusto’s Forged Check Valve is to prevent the backflow of fluids in a piping system. It does this by allowing the fluid to flow in one direction only while preventing it from flowing back in the opposite direction. This type of valve is ideal for applications where reverse flow can cause damage to equipment or contaminate the process.

BENEFITS

Gusto’s Forged Check Valve offers several benefits, including its durability and reliability. It is designed to withstand high-pressure and high-temperature applications, making it an ideal choice for harsh environments. Additionally, it has a compact design that makes it easy to install and maintain. The valve’s low pressure drop ensures efficient fluid flow and minimizes energy costs.

APPLICATIONS

Gusto’s Forged Check Valve is commonly used in a variety of industries, including oil and gas, power generation, chemical processing, and water treatment. It is suitable for use in applications where a reliable and robust valve is required to prevent backflow.

Choose Gusto’s Forged Check Valve for a reliable and durable solution to prevent backflow in high-pressure applications. Our valves are made of high-quality forged steel and are designed to withstand harsh environments. With their compact design and low pressure drop, our valves provide efficient fluid flow while minimizing energy costs. Trust Gusto’s Forged Check Valve to keep your piping systems flowing smoothly and prevent costly damage from reverse flow.

CONTACT GUSTO’S EXPERTS TODAY TO HELP YOU CHOOSE THE RIGHT VALVE !

| Sl. No. | Description | Specification |

|---|---|---|

| 1 | Body | ASTM A105 |

| 2 | Cover | ASTM A105 |

| 3 | Piston Disc | ASTM A276 Type 410 |

| 4 | Spring | SS 302 |

| 5 | Gasket | Spiral-wound SS type 304 with graphite filler |

| 6 | Cap Screws | ASTM A193 Gr. B7 |

| 7 | Identification Plate | SS |

CLASS 150 / 300

Flanged ends (in inches, unless specified)

| Valve Size inch (mm) | CLASS 150 / 300 CHECK VALVES | |||||||

|---|---|---|---|---|---|---|---|---|

| A | B | C | øD | E | ||||

| RB | FB | RB | FB | Class 150 | Class 300 | |||

| ½ (15) | 6.0 | 6.0 | 2.10 | 2.30 | 3.50 | 3.75 | 0.62 | 0.56 |

| ¾ (20) | 7.0 | 7.0 | 2.30 | 2.60 | 3.88 | 4.62 | 0.82 | 0.62 |

| 1 (25) | 8.0 | 8.0 | 2.60 | 3.50 | 4.25 | 4.88 | 1.05 | 0.69 |

| 1.1/4 (32) | 8.5 | 8.5 | 3.50 | 3.50 | 4.62 | 5.25 | 1.38 | 0.75 |

| 1.1/2 (40) | 9.0 | 11.5 | 3.50 | 4.10 | 5.00 | 6.12 | 1.61 | 0.81 |

| 2 (50) | 10.5 | – | 4.10 | – | 6.00 | 6.50 | 2.07 | 0.88 |

CLASS 600

Flanged ends (in inches, unless specified)

| Valve Size inch (mm) | CLASS 600 CHECK VALVES | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | øD | E | App. Wt. (kg) | |||||

| RB | FB | RB | FB | RB | FB | RB | FB | |||

| ½ (15) | 6.5 | 6.5 | 2.1 | 2.3 | 3.75 | 0.50 | 0.62 | 0.56 | 3.0 | 4.6 |

| ¾ (20) | 7.5 | 7.5 | 2.3 | 2.6 | 4.62 | 0.75 | 0.82 | 0.62 | 4.6 | 6.2 |

| 1 (25) | 8.5 | 8.5 | 2.6 | 3.5 | 4.88 | 1.00 | 1.05 | 0.69 | 6.2 | 9.1 |

| 1.1/4 (32) | 9.0 | 9.0 | 3.5 | 3.5 | 5.25 | 1.25 | 1.38 | 0.81 | 9.1 | 11.2 |

| 1.1/2 (40) | 9.5 | 11.5 | 3.5 | 4.1 | 6.12 | 1.50 | 1.61 | 0.88 | 11.2 | 15.2 |

| 2 (50) | 11.5 | – | 4.1 | – | 6.50 | 2.00 | – | 1.00 | 15.2 | – |

CLASS 800

Screwed / Socket-weld ends (in inches, unless specified)

| Valve size inch (mm) | CLASS 800 CHECK VALVES | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D (min) | E | G | App. Wt. (kg) | |||||

| RB | FB | RB | FB | RB | FB | RB | FB | ||||

| ¼ (8) | 3.20 | – | 2.1 | – | ¼ | 0.555 | 0.38 | 0.25 | – | 1.1 | – |

| 3/8 (10) | 3.20 | 3.20 | 2.1 | 2.1 | 3/8 | 0.690 | 0.38 | 0.25 | 0.38 | 1.1 | 1.1 |

| ½ (15) | 3.20 | 4.00 | 2.1 | 2.3 | ½ | 0.855 | 0.38 | 0.38 | 0.50 | 1.1 | 1.5 |

| ¾ (20) | 4.00 | 4.85 | 2.3 | 2.6 | ¾ | 1.065 | 0.50 | 0.50 | 0.69 | 1.5 | 2.4 |

| 1 (25) | 4.85 | 6.40 | 2.6 | 3.5 | 1 | 1.330 | 0.50 | 0.69 | 0.94 | 2.4 | 4.4 |

| 1.1/4 (32) | 6.40 | 6.40 | 3.5 | 3.5 | 1.1/4 | 1.675 | 0.50 | 0.94 | 1.17 | 4.4 | 4.4 |

| 1.1/2 (40) | 6.40 | 8.80 | 3.5 | 4.1 | 1.1/2 | 1.915 | 0.50 | 1.17 | 1.44 | 4.3 | 6.8 |

| 2 (50) | 6.40 | – | 4.1 | – | 2 | 2.406 | 0.62 | 1.44 | – | 6.8 | – |

TECHNICAL DATA

Construction : Bolted Cover

Design & Mfg. Std : As Per Api 602/ISO 15761

Insp & Test Std : As Per API 598

End Connection : Socket Weld As Per ASME B16.11

Screwed End As Per ASME B1.20.1

MOC : ASTM A105, F304, F304I, F316, F316I, F5, F9, F11, F22, Lf2.