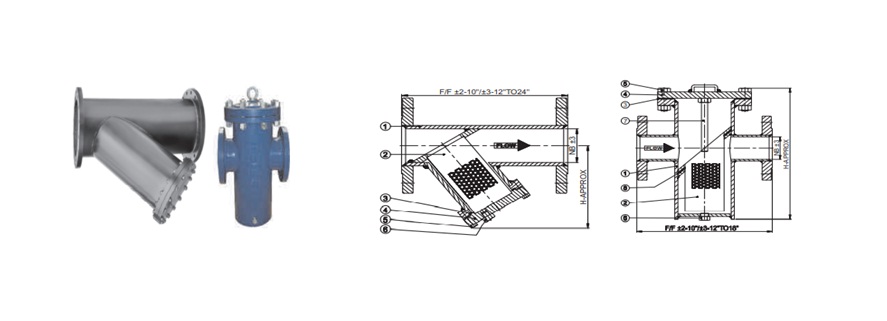

CLASS 150 MS ‘Y’ / BASKET TYPE FABRICATED STRAINER

Gusto’s Class 150 MS ‘Y’ / Basket Type Fabricated Strainer is a high-performance strainer used in industrial applications. This strainer is fabricated from high-quality materials and designed to provide maximum durability and reliability.

PURPOSE

The primary purpose of Gusto’s Class 150 MS ‘Y’ / Basket Type Fabricated Strainer is to protect equipment from contamination by removing solid particles from liquids and gases. This strainer is ideal for use in applications where high flow rates and high-pressure differentials are required.

BENEFITS

Gusto’s Class 150 MS ‘Y’ / Basket Type Fabricated Strainer offers several benefits, including high flow rates, high-pressure differentials, and low pressure drops. This strainer is fabricated from high-quality materials, making it durable and reliable. It is easy to install, maintain, and clean, ensuring minimal downtime and increased productivity.

APPLICATIONS

Gusto’s Class 150 MS ‘Y’ / Basket Type Fabricated Strainer is used in a wide range of industrial applications, including chemical processing, food and beverage processing, water treatment, and pharmaceutical manufacturing. This strainer is ideal for use in applications where a high level of filtration is required to prevent damage to equipment and to ensure product quality.

The different parameters, as well as the size and material of the valve as per the tables, illustrations and details given in this page, to ensure that our valves match the requirements of your specific application.

If you are looking for a high-performance strainer that is durable, reliable, and easy to install, maintain, and clean, Gusto’s Class 150 MS ‘Y’ / Basket Type Fabricated Strainer is the ideal choice for you. Our strainer is fabricated from high-quality materials and designed to provide maximum filtration efficiency, ensuring that your equipment is protected from contamination and your products are of the highest quality. With Gusto’s Class 150 MS ‘Y’ / Basket Type Fabricated Strainer, you can be confident that your operations will run smoothly and efficiently, with minimal downtime and increased productivity.

CONTACT GUSTO’S EXPERTS TODAY TO HELP YOU CHOOSE THE RIGHT VALVE !

| SR.No | Part Name | Material | Qty |

|---|---|---|---|

| 1 | Body | A216-WCB | 1 |

| 2 | Screen | SS-304 (40 MESH) | 1 |

| 3 | Body Gasket | SS-304 S/W GRAPHITE | 1 |

| 4 | Cover | A216-WCB/MS | 1 |

| 5 | Bolt / Nut | STEEL | REQ. |

| 6 | Drain Plug | MS | 1 |

CLASS 150 DIMENSIONS

| Size-In | 1” | 1.1/4” | 1.1/2” | 2” | 2.1/2” | 3” | 4” | 5” | 6” | 8” | 10” | 12” | 14” | 16” | 18” |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Size-mm | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 |

| NB | 25 | 32 | 38 | 50 | 63 | 76 | 102 | 127 | 152 | 203 | 254 | 305 | 337 | 387 | 436 |

| F/F | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 | 850 | 980 | 1100 | 1200 |

| H | 115 | 120 | 130 | 160 | 210 | 235 | 285 | 340 | 355 | 450 | 540 | 600 | 700 | 735 | 800 |

| Wt-kg | 4 | 5 | 6 | 8.2 | 13 | 15.5 | 26.5 | 41 | 57 | 99 | 145 | 250 | 445 | 500 | 565 |

TECHNICAL DATA

Construction : Bolted Cover ‘Y’ Type Flanged End Strainer

Design & Mfg Std : Manufacturer

Insp & Test Std : As Per API-598/BS 6755-PT-1

Face To Face : As Per ASME B16.10

End Connection : Flanged As Per ASME B16.5RF-Serrated Face