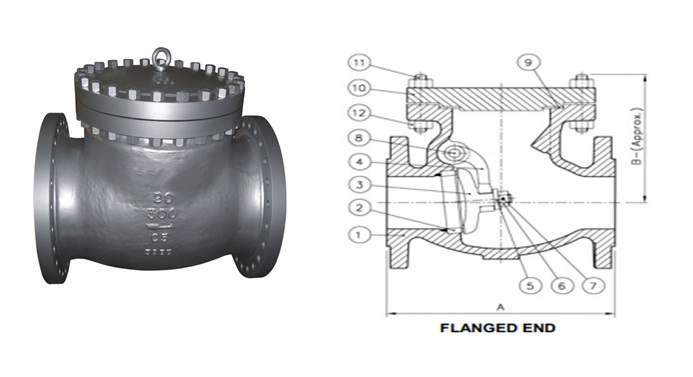

CAST SWING CHECK VALVE 150, 300, 600, 800

Gusto’s Cast Swing Check Valve is designed to prevent backflow in pipelines and maintain fluid flow direction. This valve features a swing disc that allows flow in one direction and prevents backflow when flow stops. The cast steel construction makes it suitable for high-pressure and high-temperature applications.

PURPOSE

The purpose of the Gusto’s Cast Swing Check Valve is to provide a reliable and efficient way to prevent backflow and maintain fluid flow direction. It is ideal for use in applications that require high pressure and temperature resistance.

BENEFITS

The benefits of Gusto’s Cast Swing Check Valve include its durable construction, long service life, and easy maintenance. The valve is designed to withstand harsh environments and high-pressure applications. It is also easy to install and operate.

APPLICATIONS

Gusto’s Cast Swing Check Valve is used in a variety of industries, including oil and gas, petrochemical, chemical, power generation, and water treatment. It is ideal for use in pipelines, pumps, and other systems where backflow prevention is critical.

The different parameters, as well as the size and material of the valve as per the tables, illustrations and details given in this page, to ensure that our valves match the requirements of your specific application.

If you need a reliable and efficient way to prevent backflow in your pipelines, Gusto’s Cast Swing Check Valve is the perfect solution. Our valve is designed to withstand harsh environments and high-pressure applications, making it ideal for use in a variety of industries. With its durable construction and long service life, you can trust our valve to keep your systems running smoothly for years to come. So why wait? Contact us today to learn more about how Gusto’s Cast Swing Check Valve can benefit your business!

CONTACT GUSTO’S EXPERTS TODAY TO HELP YOU CHOOSE THE RIGHT VALVE !

Standard Materials of Construction

| Sl. No. | Description | Material |

|---|---|---|

| 01 | Body | ASTM A216 Gr.WCB |

| 02 | Body Seat Ring | ASTM A105 + HF |

| 03 | Disc | ASTM A216 Gr.WCB+ 13% Cr. Steel |

| 04 | Hinge | ASTM A216 Gr. WCB |

| 05 | Disc Washer | 13% Cr. Steel |

| 06 | Disc Nut | SS 304 |

| 07 | Disc Nut Pin | 13% Cr. Steel |

| 08 | Hinge Pin | 13% Cr. Steel |

| 09 | Gasket | ASTM A308 |

| 10 | Cover | ASTM A216 Gr. WCB |

| 11 | Stud | ASTM A193 Gr. B7 |

| 12 | Stud Nut | ASTM A194 Gr. 2H |

| 13 | Hinge Pin Cover | ASTM A105 |

| 14 | Hinge Pin Cover Bolt | ASTM A193 Gr. B7 |

| 15 | Name Plate | SS 304 |

Dimensions (in mm, unless specified) & Weights (in kg)

| Valve Size | Class 150 | Class 300 | Class 600 | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | Approx. Wt, | A | B | Approx. Wt. | A | B | Approx. Wt. | ||||||||

| FI, | B/W | FI. | B/W | FI. | B/W | FI. | B/W | FI. | B/W | FI. | B/W | |||||

| 50 (2’) | 203 | 203 | 165 | 21 | 19 | 267 | 267 | 165 | 24 | 19 | 292 | 292 | 178 | |||

| 65 2.1/2’) | 216 | 216 | 175 | 24 | 20 | – | – | – | – | – | – | – | – | – | – | |

| 80 (3’) | 241 | 241 | 181 | 34 | 30 | 317 | 317 | 190 | 45 | 36 | 356 | 356 | 203 | 55 | 46 | |

| 100(4’) | 292 | 292 | 213 | 49 | 42 | 356 | 356 | 229 | 70 | 56 | 432 | 432 | 229 | 92 | 70 | |

| 150(6’) | 356 | 356 | 273 | 88 | 79 | 444 | 444 | 279 | 151 | 129 | 559 | 559 | 365 | 204 | 161 | |

| 200 (8’) | 495 | 495 | 335 | 168 | 154 | 533 | 533 | 343 | 242 | 210 | 661 | 661 | 442 | 323 | 260 | |

| 250 (10’) | 622 | 622 | 406 | 280 | 260 | 622 | 622 | 368 | 333 | 284 | 787 | 787 | 450 | 550 | 455 | |

| 300 (12’) | 698 | 698 | 483 | 413 | 382 | 711 | 711 | 412 | 450 | 378 | 838 | 838 | 590 | 790 | 680 | |

| 350 (14’) | 788 | 788 | 515 | 509 | 466 | 839 | 839 | 559 | 659 | 556 | – | – | – | – | – | |

| 400 (16’) | 864 | 864 | 455 | 580 | 524 | 864 | 864 | 636 | 873 | 747 | – | – | – | – | – | |

| 450 (18’) | 978 | 978 | 500 | 635 | 583 | 978 | 978 | 562 | 1090 | 900 | – | – | – | – | – | |

| 500 (20’) | 978 | 978 | 675 | 925 | 855 | 1016 | 1016 | 675 | 1360 | 1176 | – | – | – | – | – | |

| 600 (24’) | 1295 | 1295 | 780 | 1500 | 1403 | 1346 | 1346 | 790 | 1850 | 1573 | – | – | – | – | – | |

FI – Flanged: B/W – Butt-weld.

TECHNICAL DATA

Construction : Swing Type Check Valve, Bolted Cover, Seat Ring

Design & Mfg Std : As Per BS – 1868

Insp & Test Std : As Per API 598/BS-6755-PT-1

Face To Face Dim : As Per ASME B16.10

End Connection : Flange End As Per ASME B16.5 Class 150#

Moc : WCB/CF8/CF8M/CF3/CF3M

Trims : 13%CR./S.S.304/S.S.316/S.S.304L/S.S.316L